The best defense against the proliferation of counterfeit parts is a proactive and strategic approach that mitigates risk though, obsolescence management, maximizing use of low-risk suppliers, enhancing part availability throughout a product’s life cycle through methods such as identifying acceptable product substitutions and system redesign and Implementing robust testing and inspection measures when procuring from higher-risk suppliers.

To effectively accomplish these defenses, emphasis should be placed on up-front preventive strategies. Part Traceability, Reverse Traceability and Inspection and Testing with criteria for acceptance and rejection. Within the spectrum of destructive testing is Delid/Decapsulation Internal Analysis.

As part of these strategies, Delid/Decapsulation Internal Analysis is one of the destructive testing methods employed at Resion. While the exact technique varies depending on the packaging, Delid/Decapsulation processes expose the internal cavity or surface of the device to allow further analysis of the device via microscopy to authenticate OCM devices. This process can help to prevent the inclusion of counterfeit devices into a finished project and aid in identifying defective materials or devices that exhibit anomalies including, but not limited to corrosion, damage, and/or foreign materials introduced to the internal package cavity.

Once the internal die is exposed, it is observed and inspected utilizing high power microscopy. Our certified inspector surveils the device for indicators that deem a part “authentic” or “suspect” such as:

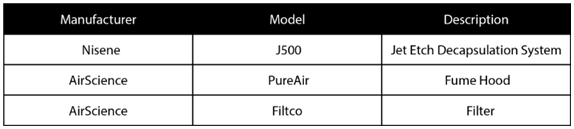

The Nisene machine utilizes a highly concentrated and controlled stream of Nitric or Sulfuric acid in which the decapsulator removes a precise amount of the body of a plastic packaging to expose the components die. X-Ray inspection, which is performed before Decapsulation, helps in pinpointing where the die is inside the component for better accuracy in this process.

This machine and acid are only used for the Decapsulation of Plastic components. For Ceramic components, hand tools are used to remove the top portion of the device from the bottom in which then we can inspect the internal makeup of the part and die markings.

Reviewed under magnification, a Resion Certified Inspector can establish if the markings on the die correlate to the specifications and exterior marking of the component. Additionally, if the manufacturer’s data sheet provides a schematic drawing of the die, it can be utilized to indicate authenticity. Comparison between units (Ex: a 3-piece sample) or a golden sample can be used in helping authenticate the die as well.

Resion keeps a library of all tested parts, along with component engineering resources, for the availability to compare previous parts tested, and as another way to help authenticate die part markings.